Silicon carbide (SiC), also known as carborundum, is a compound of silicon

and carbon with chemical formula SiC.SiC is a Ⅳ-Ⅳ compound semiconductor

material, with a variety Allotropic. The typical structure of which is divided

into two types, first type is sphalerite crystal structure as 3C-SiC

(β-SiC),second type is wurtzite hexagonal crystal structure; typically a

6H-SiC, 4H-SiC and 15R-SiC known as α-SiC. The most commonly used in the

semiconductor industry are 4H-SiC and 6H-SiC structures.

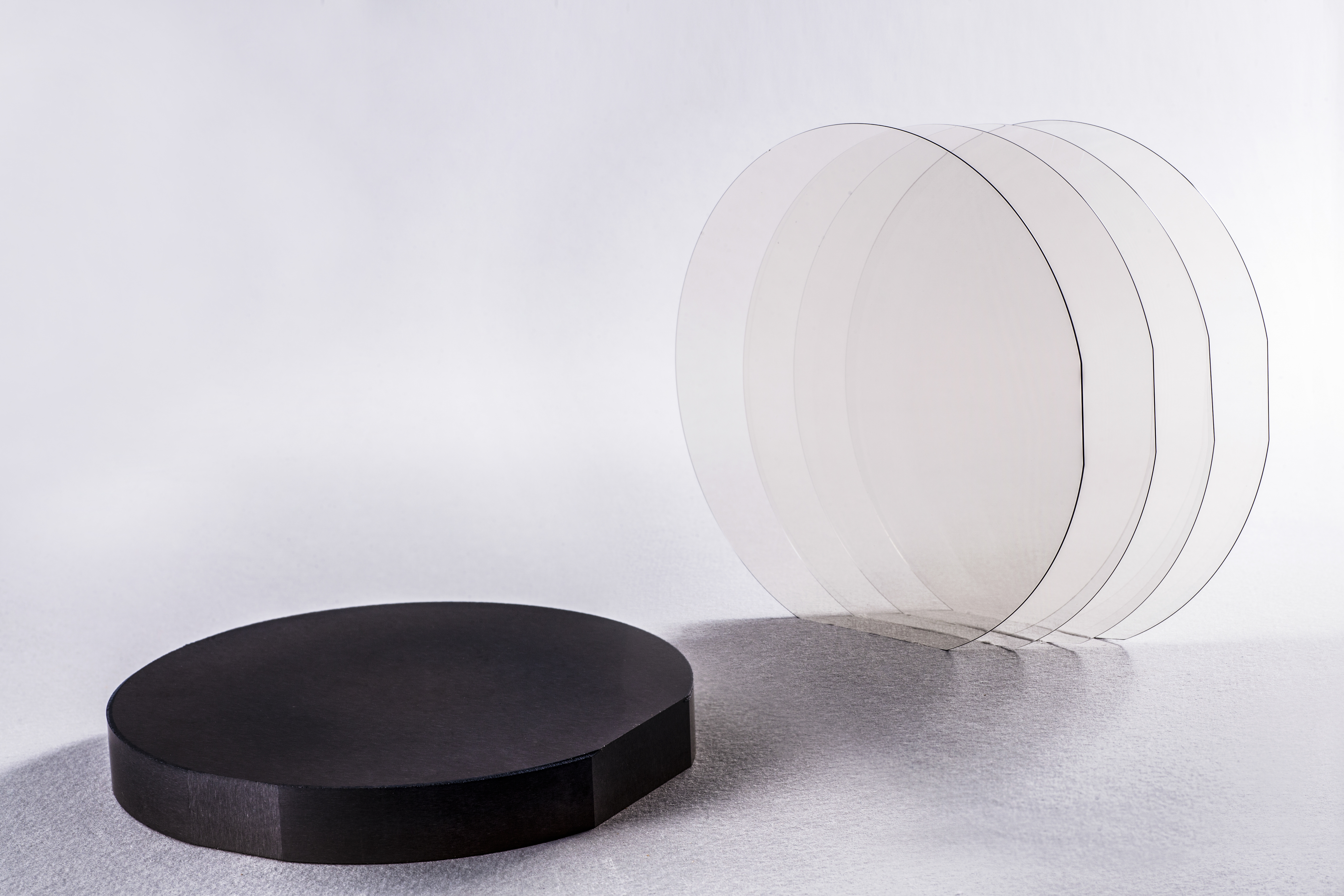

There are some advantages for SiC:

–Current density can easily reach 5 or even 10 A/mm² (less than 1 A/mm² for silicon)

–Breakdown voltage (Volt/μm of epilayer) is typically in the 100 V/μm range for SiC, compared to 10 V/μm for silicon

–A single SiC device will drive higher current and voltage in a reduced foot-print.

–SiC is intrinsically very thermally conductive. Where a Silicon device will

have to be cooled down to not exceed 85°C, a similar SiC device will operate at

250°C with no degradation. This robustness to higher operation temperature will allow cost savings at system or module level where the cooling features (air, water, fans, heat sinks…) will be considerably reduced and shrunk.

•Higher electron mobility of SiC also permits higher frequency operation in

switching mode.

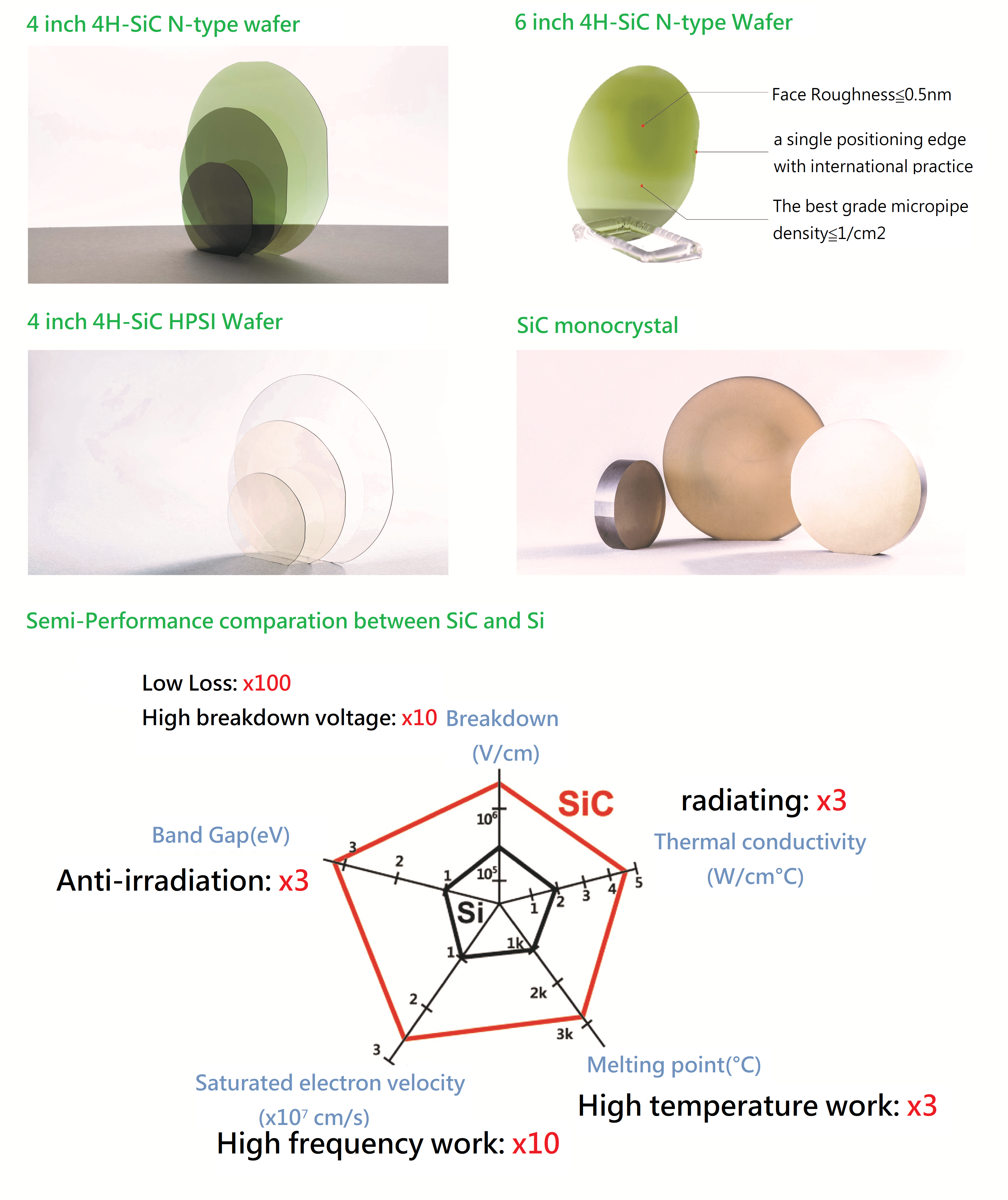

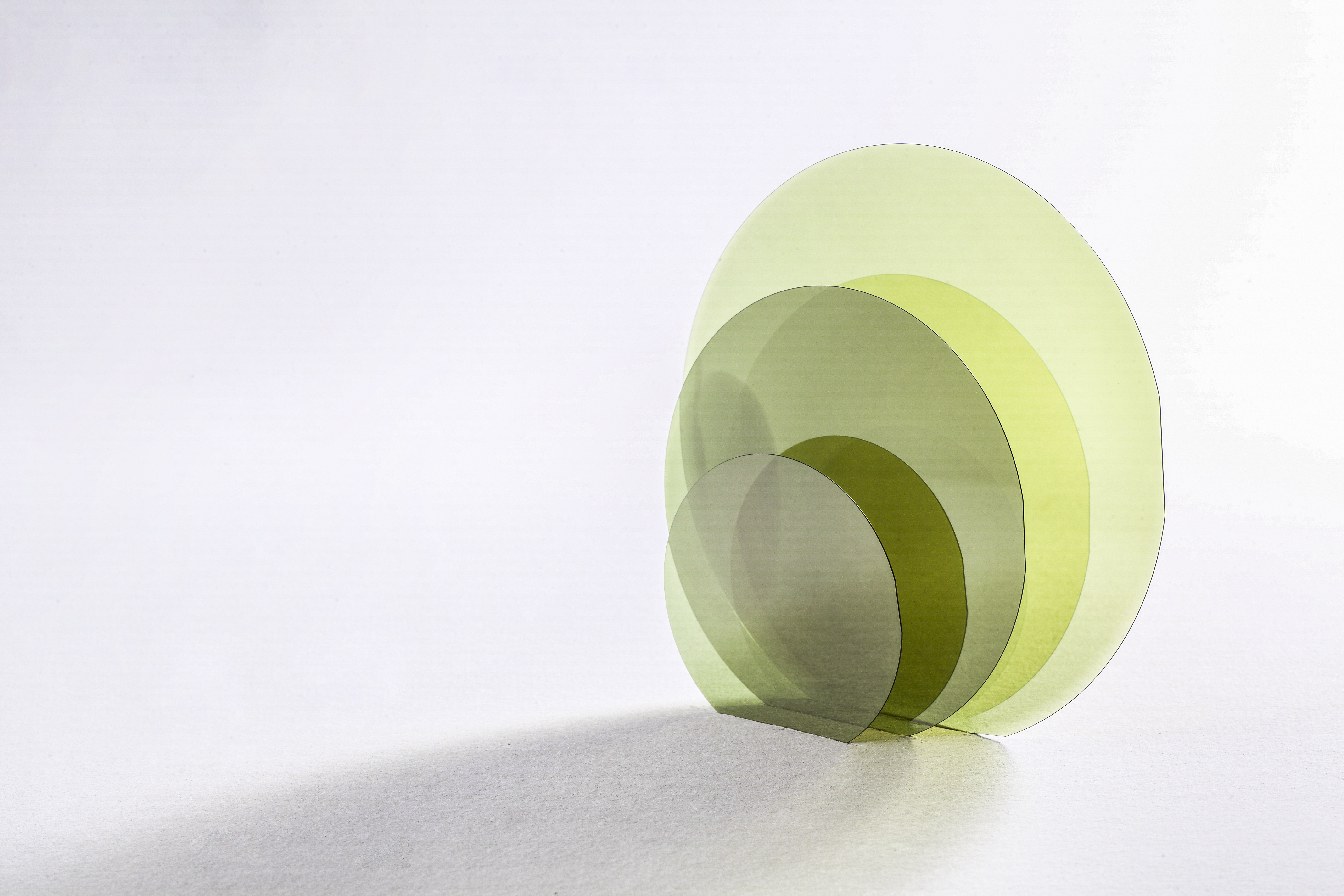

Latentek can provide high quality single crystalline Silicon carbide wafer; furthermore,

we provide two forms of wafer : semi-insulating and conductive as to meet the

customer needs of high-frequency components and high power components. Current

technical ability is able to provide MPD<1 specifications of the wafer.

|

4-inch Specifications

of 4H-SiC

High-Purity Semi-Insulating Substrate

|

| Property |

Production grade |

Research grade |

Dummy grade |

| Diameter |

100.0mm+0.0/-0.5mm |

| Surface Orientation |

{0001}±0.2° |

| Primary Flat Orientation |

<11-20>±5.0° |

| Secondary Flat Orientation |

90.0° CW from Primary Flat

±5.0°, Si Face up |

| Primary Flat Length |

32.5mm±2.0mm |

| Secondary Flat Length |

18.0mm±2.0mm |

| Wafer Edge |

Chamfer |

| Micro Pipe Density |

≦5micropipes/cm2 |

≦10micropipes/cm2 |

≦50micropipes/cm2 |

| Polytype Area by

High-intensity Light |

None |

≦10% of

Whole Area |

| Resistivity |

≧ 1E7Ω‧cm |

(Area75%)≧ 1E7Ω‧cm

|

| Thickness |

500.μm±25.μm

or 350.0μm±25.μm |

| TTV |

≦10μm |

≦15μm |

| Bow (Absolute Value) |

≦25μm |

≦30μm |

| Warp |

≦45μm |

| Surface Roughness |

Si-Face CMP Ra ≦0.5nm |

N/A |

| Cracks by High-intensity

Light |

None |

| Edge Chips/Indents by

Diffuse Lighting |

none |

Qty. ≦2,the length

and width of each<1.0mm |

|

|

4-inch

Specifications of 4H-SiC N-type

Substrate

|

| Property |

Ultra Grade |

Production Grade |

Research Grade |

Dummy Grade |

| Diameter |

100.0mm+0.0/-0.5mm |

| Surface Orientation |

Off-axis:4°

toward<11-20>±0.5° |

| Primary Flat Orientation |

<11-20>±5.0° |

| Secondary Flat Orientation |

90°

CW from Primary Flat±5.0°,

Si Face Up |

| Primary Flat Length |

32.5mm±2.0mm |

| Secondary Flat Length |

18.0mm±2.0mm |

| Wafer Edge |

Chamfer |

| Micropipe Density |

≦1micropipe/cm2 |

≦5micropipe/cm2 |

≦10micropipe/cm2 |

≦50micropipe/cm2 |

| Polytype Area

by High-intensity Light |

None |

≦10%

of Whole Area |

| Resistivity |

0.015Ω ‧ cm~0.028Ω ‧ cm |

(Area75%)0.015Ω‧cm

~0.028Ω ‧ cm

|

| Thickness |

350.0μm±25.0μm

or 500.0μm±25.0μm |

| TTV |

≦10μm |

≦15μm |

| Bow(Absolute Value) |

≦25μm |

≦30μm |

| Warp |

≦45μm |

| Surface Finish |

C Face Polished; Si Face CMP |

| Surface Roughness |

Si Face CMP Ra≦0.5nm |

N/A |

| Cracks by High-intensity

Light |

None |

| Edge Chips/Indents by

Diffuse Lighting |

None |

Qty≦2, the length

and width of each<1.0mm |

|

|

6-inch

Specifications of 4H-SiC N-type

Substrate

|

| Property |

Standard |

| Diameter |

150.0mm±0.25mm |

| Surface Orientation |

4°

toward<11-20>±0.5° |

| Primary Flat

Orientation |

<11-20>±5.0° |

| Secondary Flat Orientation |

N/A |

| Primary Flat Length |

47.5mm±2.0mm |

| Secondary Flat Length |

None |

| Wafer Edge |

Chamfer |

| Micropipe Density |

≦5/cm2 |

| Polytype Area

by High-intensity Light |

None |

| Resistivity |

0.015Ω ‧ cm~0.028Ω ‧ cm |

| Thickness |

350.0μm±25.0μm |

| TTV |

≦10μm |

| Bow(Absolute Value) |

≦40μm |

| Warp |

≦60μm |

| Surface Finish |

Double Face Polished;Si Face CMP |

| Crack by High-intensity

Light |

None |

| Edge Chips/Indents by

Diffuse Lighting |

None |

|

|

Photo Gallery of our product |