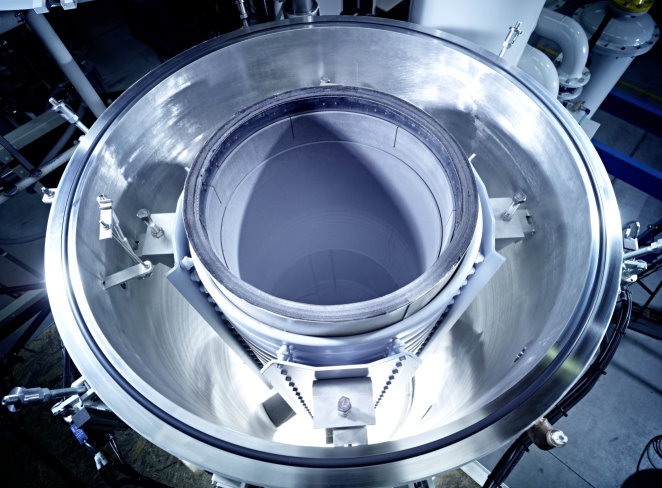

PVA TePla started business from vacuum equipment two decades ago, which means that we already have a lot of experience in the high-temperature and high-pressure atmosphere furnace. We can offer our customers with high temperature and high pressure furnaces. The market share of our furnaces is over 50% in the world. Our furnaces’ temperature can be as high as Celsius 3,000 degrees. We can create environment for specified gas which includes chlorine, argon, saline, nitrogen etc..

What we are able to do:

- Temperature up to Celsius 3,000 degrees

- Gas pressure up to 100 bar or vacuum

- Variety of Specified gases

- Fast Cooling design

- Precise temperature control

- Graphite heater or Molybdenum heater

The applications of our product in vary Industries:

- SiC mono-crystal growing:

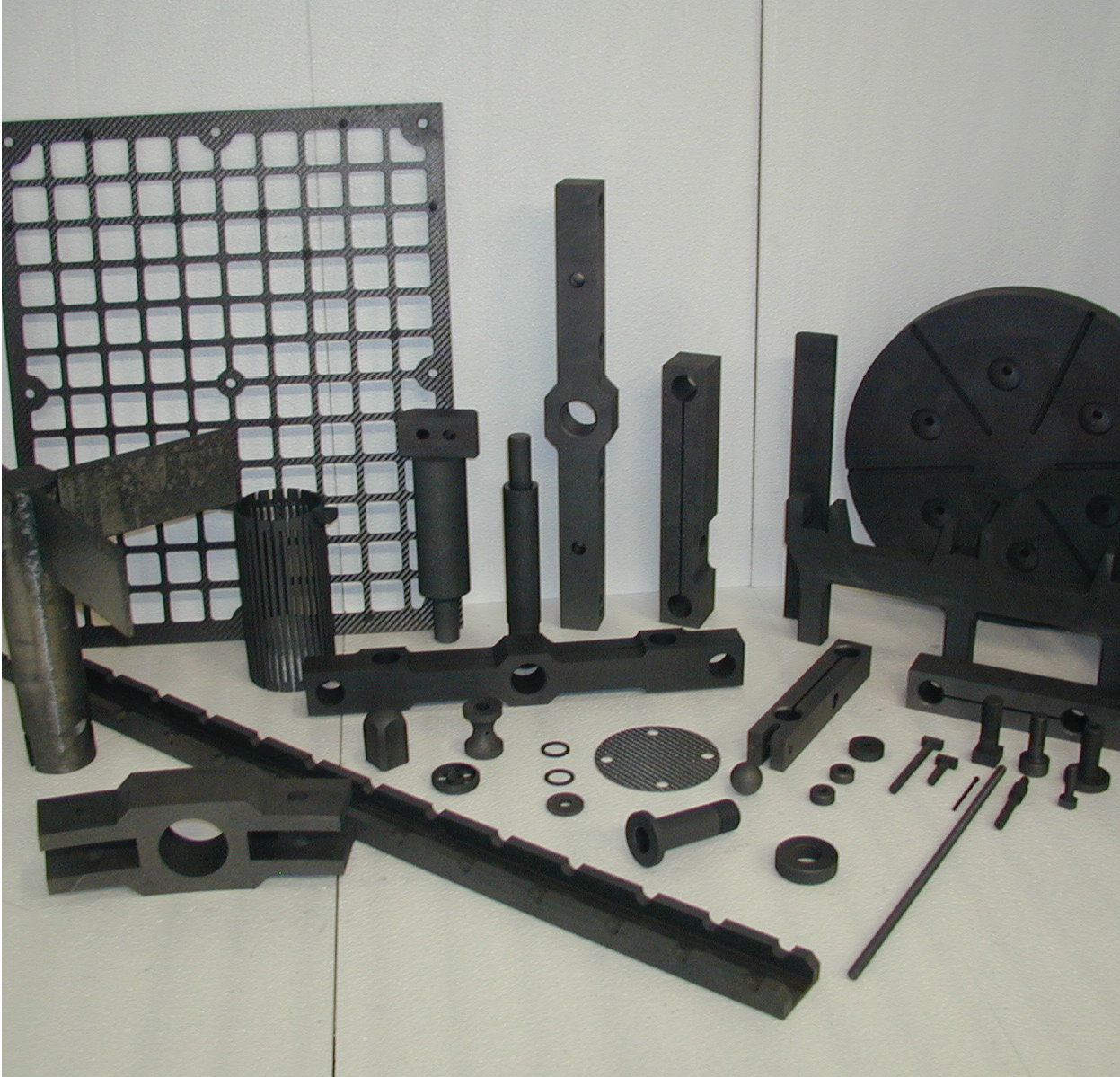

- Graphite Manufacturing:

- Purification Increasing raw material prices and increasing requirements of the purity of materials enable new applications。

- Graphitization

- PyC-Coating

- SiC-Coating : Silicon carbide(SiC) coating has benn discussed widely in recent years; however, this technology is still being held by few companies. Our clients, include international graphite manufacturers, develop high quality SiC-coating components to customers in semiconductor, LED and solar industries by our furnances..

- Induction- heat Treatment furnaces for:

- Carburizing

- Sintering

- Degassing

- Purification

- Vacuum Induction Melting and Casting Systems for:

- Graphite-heated Pressure Treatment Furnaces for:

- Dewaxing

- Sintering

- Hot-isostatic pressing of hard metals with pressure

- Graphite-heated Vacuum Treatment Furnaces for:

- Soldering

- Degassing dewaxing

- Sintering

- Purification

- CVD Coating

- Graphitization of composites

- Metal-heated High Vacuum Furnaces for:

- Brazing

- Degassing

- Annealing

- Sintering

- Hot presses High Vacuum Furnaces for:

- Diffusion bonding

- Annealing

- PulsPlasma® nitriding for surface hardening

Due to the characteristics of high temperature and chemical stability, SiC mono-crystal structure has gradually attracted attention. PVA TePla can provide 2 kinds of crystal growth method, including high-temperature chemical vapor deposition (HTCVD) and high temperature sublimation method (HTCVT, also known as PVT method). Both equipments are suitable for academic or R&D institutions.

Gold, Platinum, Silver and High purity alloys