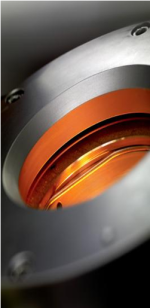

CGS was a spin off from Leybold-Heraeus Systems, focusing on the construction of crystal growing systems for the semiconductor industry. One of the methods that we use to grow crystalline ingot in the solar industry is called Czochalski method(CZ). In the CZ process, high-purity, polycrystalline silicon is put into the quartz crucible of a monocrystal growing system. Next, the process room is evacuated and the silicon is then melted down in an argon controlled atmosphere via resistive heating. After temperature stabilization of the melt (aprrox. 1420°C), a rotating monocrystalline seed crystal is dipped into the melt. As the result of a slight temperature decrease, crystallization of silicon material on the seed crystal is now initiated. As the seed is slowly pulled upwards, a cylindrical silicon moncrystal hanging on the seed crystal is then formed.

The pulling speed and the temperature are regulated in such a way that a silicon moncrystal whose orientation and structure corresponds to the seed crystal can be grown with a constant diameter.

Nowadays more and more companies start to use CZ method to grow mono ingot. Even though the process is quite complex and the cost of ownership is quite high, the conversion efficiency is much higher than the multi ingot. Also, the maturity of technology and the cell stability make the mono ingot become more competitive in the solar industry.